MUD PUMPS

Belt and Chain Transmission Series

GD Series

MUD PUMPS CONFIGURATIONS AND DESIGNS

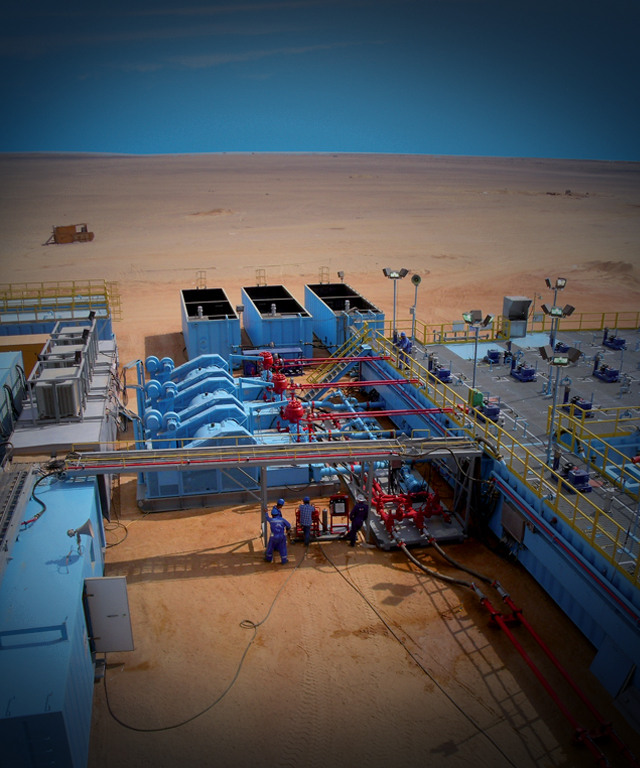

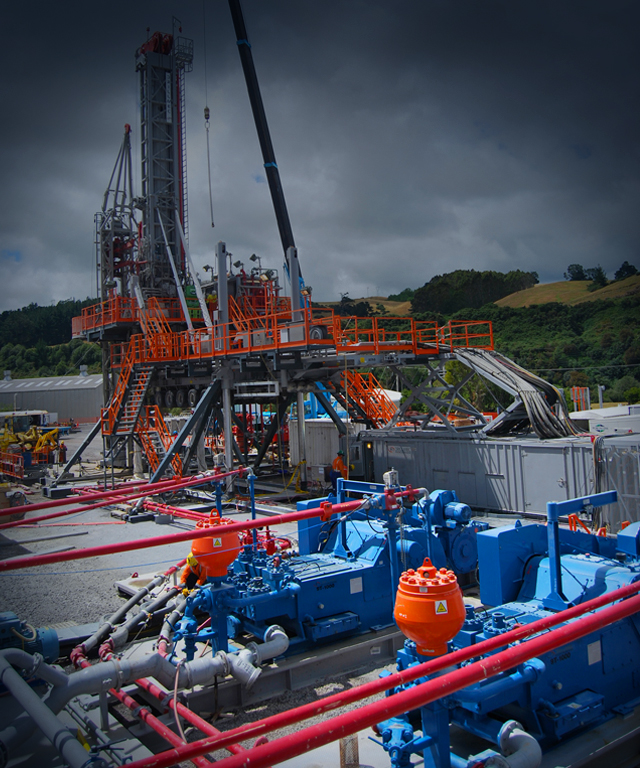

Mud pumps are akin to the heart, they are key equipment in oil and gas drilling that pumps and circulates the drilling mud. As a key player in the manufacture and sales of oilfield equipment, we have a complete range of triplex mud pumps with compact design, reduced carbon emission, and improved performance.

Our classes of onshore and offshore mud pumps range from 450 to 2,200 hp diesel or electric (AC or DC) powered with 3000 to 5000 psi ratings. We design our mud pumps to match different rig types, work optimally and safely both onshore and offshore.

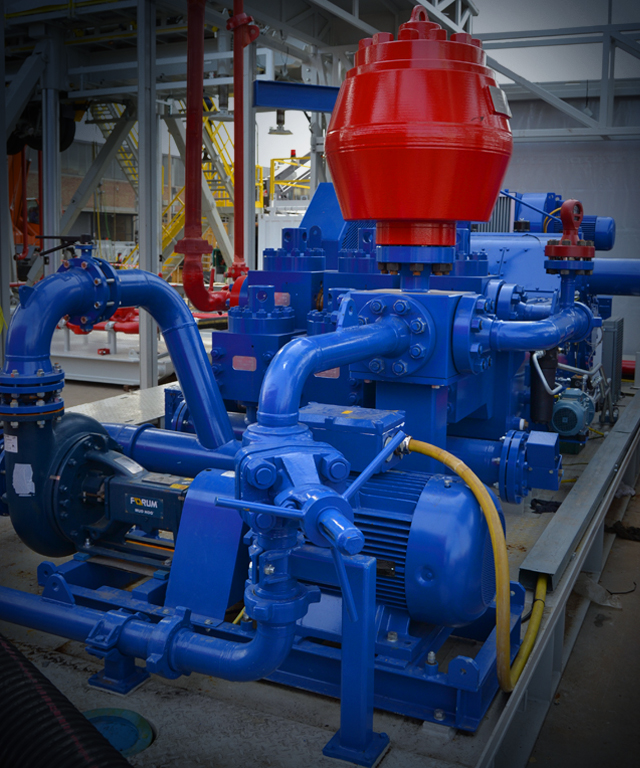

Features Of the Belt and Chain Transmission Series

This series features robust pumps designed to deliver the highest HSE standards and performance.

• Linear Range of between 114 mm to 184 mm (4 ½ -9 ¼ inches).

• Stroke range of 305 mm (12 inches).

• Maximum pressure of 517 bar (7,500 PSI).

• Maximum volume delivery of 771 gpm (2,922 l/min).

• Ratings range of 1,194 kW (1,600 hp).

• A maximum speed of 120 spm

Features Of the Gear-Driven Series

This series features low noise and low vibrations, high reliability, and a massive 25% reduction in weight.

• Linear Range of between 114 mm to 229 mm (4-9 inches).

•Stroke range of between 178 mm to 355.5 mm (7 to 14 inches).

• Maximum pressure range of between 207 bar to 517 bar (3,000 to 7,500 PSI).

• Maximum volume delivery range of between 323 gpm to 1,272 gpm (1,226 to 4,815 l/min).

• Rating range of between 336 kW to 1,640 kW (450 to 2,200 hp).

• Maximum speed range of between 110 spm to 150 spm.

KEY FEATURES OF OUR MUD PUMPS

Our mud pumps design has reduced weight, fewer vibrations, and a low noise level emission with improved reliability plus reduced NPT.

We design our mud pumps to have a top or rear-mounted motor configurations making them more compact such that 3 pumps can fit in a space of 2 pumps. This compact design also reduces carbon footprint.

Integration of P-Quip system allows for easy and faster replacements of parts such as valves, rods, liners, and others thus reducing downtime while increasing high HSE standards.

The integration of DEEP (Drillmec’s Embedded Efficiency Platform) in our mud pumps design brings advanced technology and automation to the mud pump controls and operations.

Specs

| Max Speed | Liner Range | Stroke | Max Pressure | Max Delivery | Rating | |

|---|---|---|---|---|---|---|

| rpm | mm in | mm in | bar PSI | l/min gpm | kW hp | |

| 7T450 | 150 | 114-140 4 1/2-5 1/2 | 178 7 | 207 3,000 | 1,226 323 | 336 450 |

| 7TS600 | 150 | 102-178 4-7 | 178 7 | 345 5,000 | 1,986 524 | 447 600 |

| 9T1000 | 150 | 114-178 4 1/2-7 | 228 9 | 345 5,000 | 2,554 674 | 600 1000 |

| 9T1300 | 114-178 4 1/2-7 | 228 9 | 345 5,000 | 2,554 674 | 970 1,370 | |

| 12T1600 | 120 | 114-184 4 1/2-7 1/4 | 305 12 | 345/517 5,000/7,500 | 2,554/2,922 674/771 | 1,194 1,600 |

| 14T2200 | 110 | 127-229 5-9 | 355,5 14 | 517 7,500 | 4,815 1,272 | 1,640 2,200 |

| 12T1600GD | 120 | 114-184 4 1/2-7 1/4 | 305 12 | 517 7,500 | 2,922 771 | 1,194 1,600 |