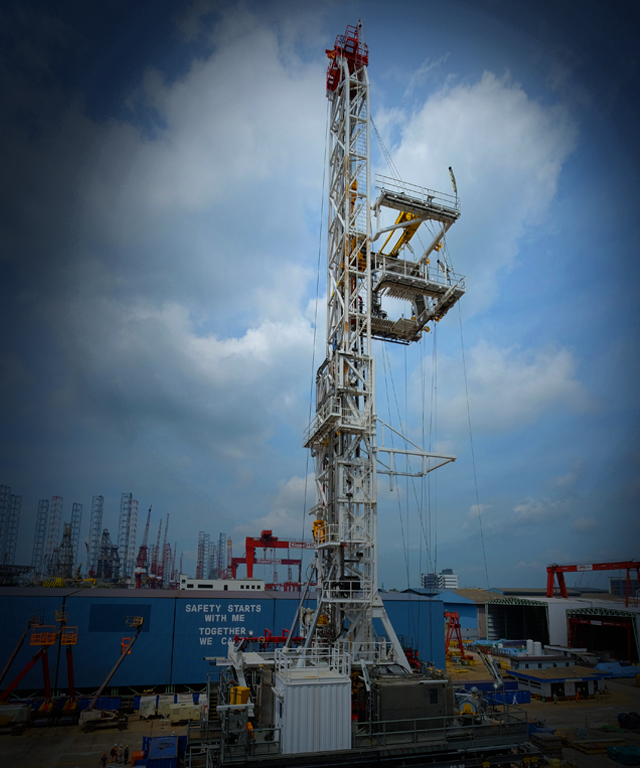

PIPE HANDLING SYSTEMS

Pipe handling systems are an integral part of oil and gas drilling operations. At Drillmec, we design and manufacture automated pipe handling systems that meet and surpass today’s requirements for efficient and safer handling of tubular. Our automated pipe handling systems are designed for easy and safe operations while delivering high output. A rig equipped with our pipe handling systems delivers greater efficiency and safer drilling operations.

Our user-friendly systems are designed to perform at a high level of safety and efficiency while delivering tubular between the pipe rack area and the drill floor. Besides the advanced racking boards with automated hydraulic or pneumatic latches plus stand racker and marker systems, we also have conventional racking boards for conventional rigs. Although the driller has full control of the system from the control cabin, we design all our systems to function with the aid of a Programmable Logic Controller (PLC) for process and sequence automation.

SOME FEATURES OF OUR AUTOMATIC PIPE HANDLING SYSTEMS

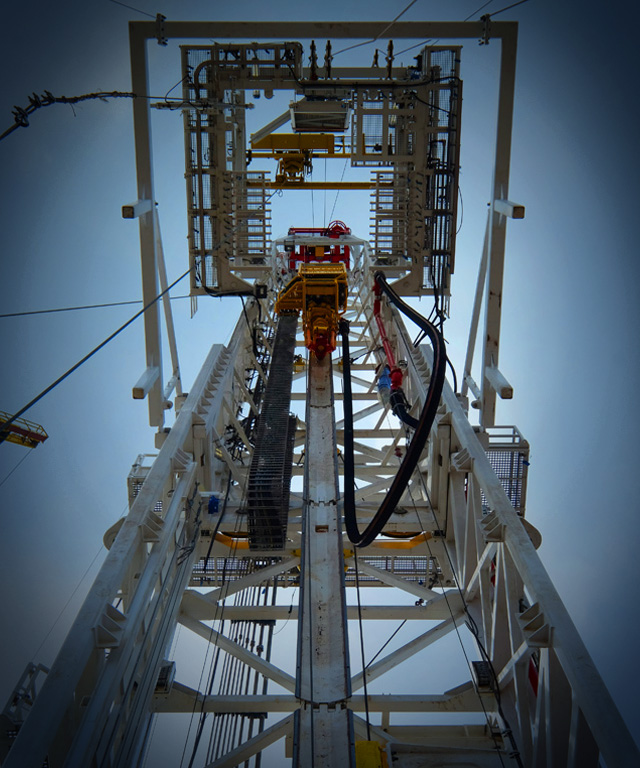

• Consists of two stationary derrick-mounted bridge travel rails.

• Features a winch and elevator that does the hoisting of the tubular.

• The maximum tubular capacity of 5000 lbs (2226 kg).

• Has a secondary trolley/ hoist assembly rolling on the bridge assembly to provide x-y motion.

• Absolute encoder feedback monitors the position of the bridge, trolley and hoist.

• Motion stop buffer eliminates collision with the top drive system.

• Mounted on runway beams installed over the racking area inside the derrick.

• Contains safety shear pins and safety cables to prevent damage in the event of a collision.

• Maximum tubular capacity of 33000 lbs (15000 kg).

• Has an anti-collision system that prevents accidental collision.

• Consists of several mobile bins with a pipe handler installed a vertical rotating tower in the middle.

• Clamps grab and transfer pipe to the mouse hole from the bins.

• Maximum tubular capacity of 13228 lbs (6000 kg).

• Uses hydraulic tongs which enhance safety.

• Can be transported fully loaded with pipe which reduces pipe handling procedures.

• Consist of one hydraulic mechanical arm with a clam and a vertical movable trolley.

• Offline build-up pipe stands which save tripping and make-up time.

• Maximum tubular capacity of 13228 lbs (6000 kg).

• Picks a pipe from the conveyor system at drill floor level and raise/rotate it in a vertical position in correspondence to the top drive.

• Latches on the mast by the means of a hook and ten flanges tightened with bolts

• Maximum tubular capacity of 3306 lbs (1500 kg).

• Can be integrated into Drillmec Hydraulic Drilling Rigs and Skid-mounted rotary drilling & workover rigs.

• Allows for build-up and rack back stands of tubular offline while drilling.

• Offline stands build-up leads to a 20% efficiency gain on tripping time.

• Maximum tubular capacity of 2800 lbs (1400 kg) in automatic mode.

• Has automatic and semi-automatic sequences of handling tubular which enhances safety.

Specs

| PIPE HANDLING EQUIPMENTS | Racking Board Capacities | Max Tubular Capacities | Tubular Range |

|---|---|---|---|

| " | kg lbs | ||

| X-Y Racking Board Racker | Drill Pipe up to 5"OD. Drill Collars up to 8"OD. | 2226 5000 | |

| Bridge Crane Racker | Drill Pipe up to 6 5/8"OD. Drill Collars up to 9 3/4"OD. | 15000 33000 |

| PIPE HANDLING HH SERIES | Racking Board Capacities | Max Tubular Capacities | Tubular Range |

|---|---|---|---|

| " | kg lbs | ||

| Vertical Racker | 6000 13228 | Drill Pipe from 3 1/2” thru 5”OD, Drill Collars from 4 3/4” thru 9 1/2 OD API Range 3 Single | |

| HH220 ICU Pipe Handling Machine | 1500 3306 | Drill Pipe or tubing from 2 3/8” thru 9 3/8”OD API Range 3 Single | |

| Vertical Pipe Handler Automatic HH | 6000 13228 | Drill Pipe or Drill Collars from 2 3/8” thru 9 3/8”OD API Range 3 Single |